Savage Patriot Polymers

POLYKOTE Enhanced™- No Odor- UV Countertop Coating (1.5 Gallon Kit) 30-35 min. Working Time. Thicker like epoxy

POLYKOTE Enhanced™- No Odor- UV Countertop Coating (1.5 Gallon Kit) 30-35 min. Working Time. Thicker like epoxy

Couldn't load pickup availability

This isn't epoxy; but it feels and acts like it. This version is much thicker than PolyKote original and pro. Designed to lay thicker and to be more "Epoxy Like" without worrying about yellowing. This Hybrid coating is engineered for longevity. While traditional epoxy may initially impress, it inevitably succumbs to yellowing and dullness over time. Enter Savage Patriot's PolyKote Enhanced Coating – a game-changer for the countertop coating industry. Offering the same versatility as epoxy but with superior strength and UV resistance, and now Advanced Hardness with NO VOC'S!!

Yes, it comes at a slightly higher cost than epoxy, but for good reason. The premium raw materials required for PolyKote Enhanced's production surpass those of epoxy. If you're seeking short-term savings on a few dollars, this isn't the solution for you. However, if your priority is long-term durability and avoiding callbacks from clients unhappy with deteriorating countertops, then PolyKote Enhanced CT is your answer.

30-35 Minute working time.

Note: All PolyKote products require a protective topcoat. Due to the Polymerization the substrate can experience shrinkage leaving a slight orange peel or slight micro crystals in surface. This is normal. Sanding and applying the topcoat will flatten the surface and protect it.

**PolyKote Enhanced Preparation**

Ensure the substrate is sanded well before and in between coats with 220 grit and is clean, dry, and free from any contaminants before application. Clean surface after sanding with water within the first 24hrs or isopropyl alcohol after 48hrs; let dry fully before applying PolyKote to surface. It is recommended to prime the surface with a paint and primer (Not a urethane modified) and let fully cure. Do not use in outdoor applications, or use modified urethane based primer coats, or siliconized acrylic primers as a base coat prior to applying PolyKote.

**Directions**

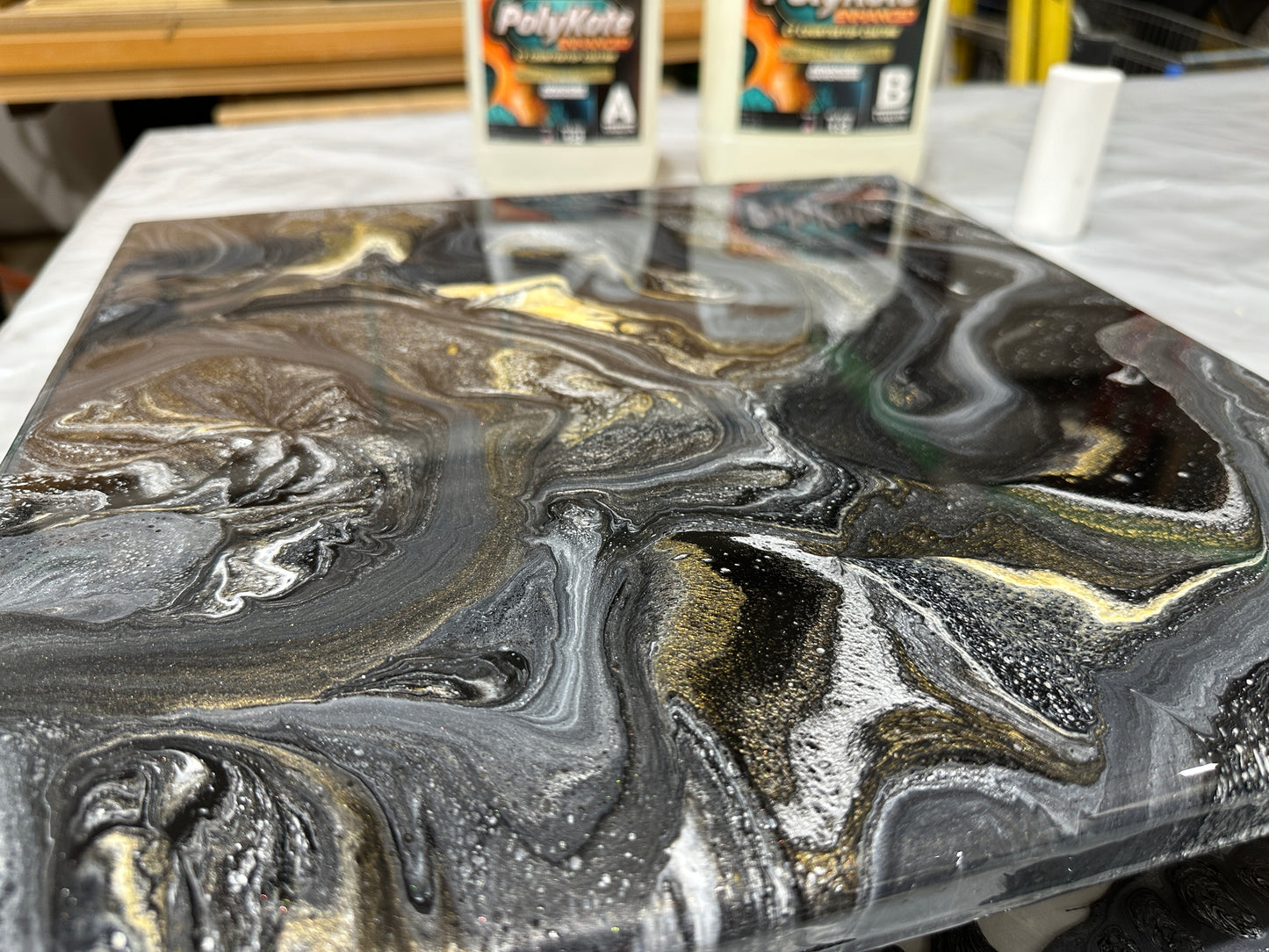

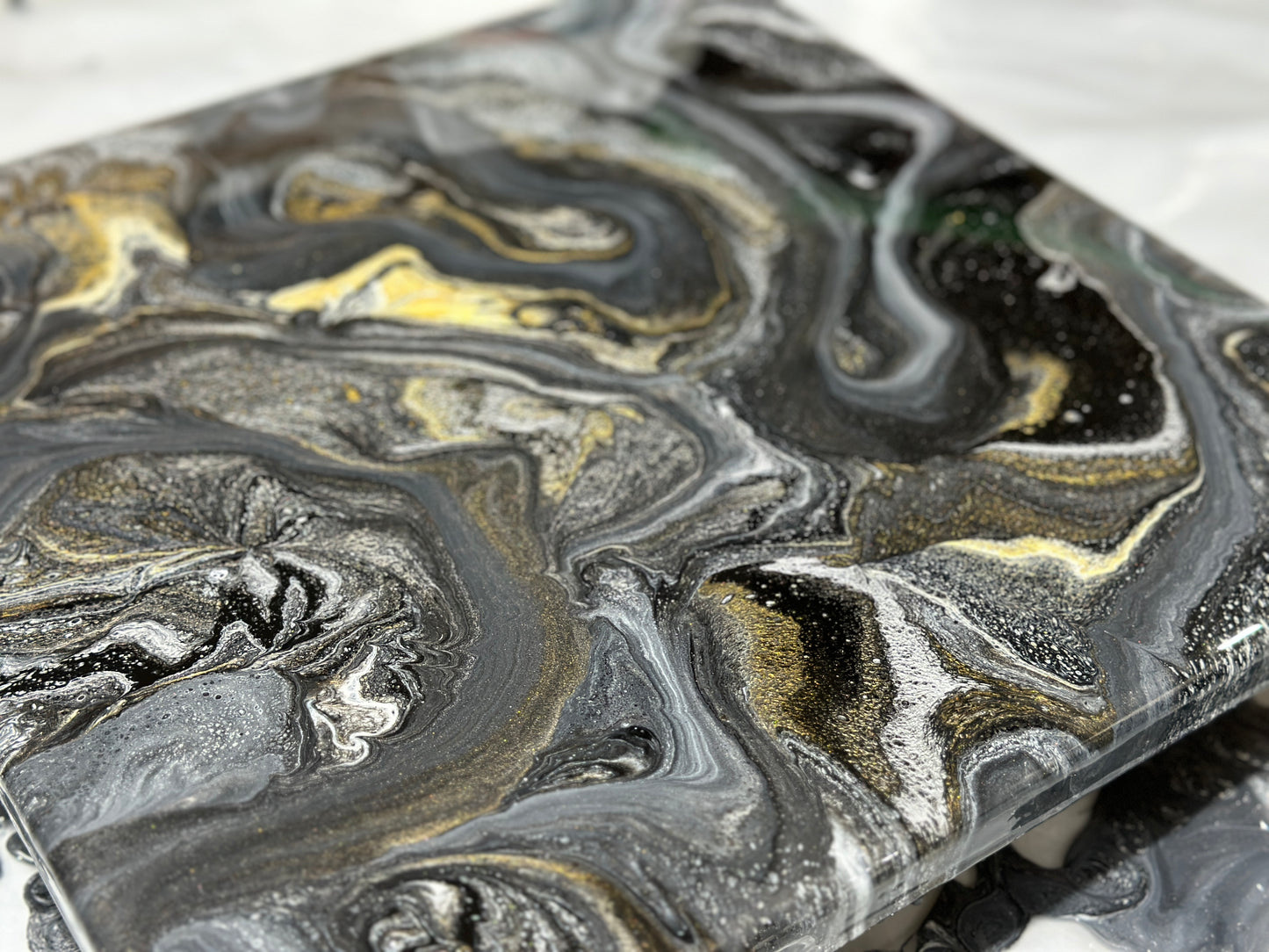

1(A):2(B) Mix Ratio, Mix slow for 2-3 minutes. Mixing with paddle mixer slowly is recommended. 1.5-Gallon Kit yields approximately 45-60 SF per kit, depending on application (3-5OZ per SF). This “CAN” be poured using dirty pour techniques unlike the original. Heat Resistant, NON-Yellowing, Impact Resistant, Water Resistant, Easy to Clean, NO VOC. Torching is recommended for most jobs. Just Add Savage Patriot metallic pigment, solid tints, and more!

**Additives:**

Tint PolyKote Enhanced with additives that are UV stable and apply to the surface using a roller, hands, or squeegees. Savage Patriot Polymers has tested all our in-house tints and colorants.

The general rule for tinting epoxy or PolyKote is to not exceed 5-10% by volume of the total mixed resin and hardener.

• Ideal range: 2-5% for most applications to maintain curing integrity.

• Max limit: 10%, but exceeding this can lead to curing issues, softness, or incomplete hardening.

If you’re using pigment powders, you can usually stay around 2-5%. For liquid dyes, it’s best to start lower since some contain solvents that can affect curing. Always mix thoroughly and test a small batch before committing to a full pour.

Recommended for Indoor use only.

**Note: For Additives**

Despite these measures, some additives used in materials may not be UV stable themselves. For example, certain types of colorants or fillers may be prone to UV-induced degradation or discoloration over time. When these additives degrade, they can sometimes impart an amber hue to the material. This phenomenon is often observed in plastics, paints, and coatings that are not specifically formulated for UV stability.

The process by which non-UV stable additives amber over time involves chemical reactions triggered by UV radiation. UV exposure can break chemical bonds in these additives, leading to the formation of chromophores, which are responsible for the amber coloration. Additionally, oxidative processes can occur, further exacerbating discoloration. In summary, PolyKote Enhanced is UV stable due to its formulation, which incorporates UV stability. However, materials that lack these UV-stabilizing features may experience ambering over time as UV-sensitive additives degrade in response to sunlight exposure.

**Drying/Curing Time:**

PolyKote Enhanced will be dry to the touch in approximately 2-3 hours at a temperature of 70 degrees Fahrenheit and cured after 24 hrs. In cases of high humidity, or lower temps, expect longer or slower cure times. Epect full cure time to be 20-30 days depending on location. Use gently during this time. Note: Please keep in mind that PolyKote has a 60% elongation, while epoxy may only have an elongation of around 3%. As a result, PolyKote is more flexible and may show indentations when heavy items are placed on it for extended periods. It’s important to understand why this occurs. Over time, epoxy tends to become brittle and is more prone to cracking or failure. In contrast, PolyKote has superior memory and flexibility, so even if an area shows slight indentations, it will return to its original form. To prevent long-term indentations from heavy weight, it’s always recommended to use placemats or protective pads under heavy items throughout the life of the coating.

**Cleaning Application Tools:**

Use Isopropyl Alcohol to clean application tools immediately after use to prevent the product from hardening.

**Shelf Life:**

The shelf life of PolyKote Enhanced is 1 year from the date of manufacturing. Store PolyKote Enhanced in a cool, dry place away from direct sunlight to maintain product integrity.

**Storage:**

Keep PolyKote Enhanced in a cool, dry storage area away from direct sunlight. Ensure the container is tightly sealed after each use to maintain product integrity.

**Safety Precautions:**

- Keep PolyKote Enhanced out of reach of small children to prevent accidental ingestion.

- In the event of contact with eyes, immediately seek medical attention.

- If ingested, seek medical attention promptly.

- Personal Protective Equipment when installing is recommended.

- Zero VOC- 100% Solids content.

- Food Contact: FDA 21 CFR 175.300 https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=175.300

- Allergic reactions can vary from person to person.

**Note:** This user guide serves as a general guideline. For specific application instructions and safety precautions, always refer to the product label and consult with a professional if needed.

Share